In today's high-stakes construction environment, general contractors face unprecedented pressure to deliver projects on time, on budget, and in compliance with increasingly stringent regulations. While many factors contribute to project success, effective management of airborne contaminants has emerged as a critical differentiator that impacts both regulatory compliance and project outcomes.

The Hidden Costs of Poor Air Quality on Construction Sites

Before diving into solutions, it's important to understand what's at stake. According to EPA estimates, poor indoor air quality costs tens of billions of dollars annually in lost productivity and increased healthcare costs across all industries, with construction particularly vulnerable due to high levels of airborne contaminants.

On construction sites specifically, airborne hazards create multiple potential cost centers—though their impact varies significantly by project type:

-

Rework Expenses: Dust contamination of finishes and equipment can necessitate costly rework, particularly in high-finish environments

-

Regulatory Penalties: OSHA citations for specific contaminants like silica dust (29 CFR 1926.1153), welding fumes (29 CFR 1926.353), and other regulated substances can result in significant fines—but only when these specific activities are present

-

Productivity Impacts: The EPA estimates that poor air quality can reduce productivity by 3-7% in general workplace environments.

-

Schedule Considerations: Work stoppages related to air quality issues can add days to project timelines on regulated activities.

-

Warranty Implications: Post-occupancy issues related to dust in HVAC systems and other components can trigger warranty callbacks in sensitive installations

"What many contractors don't realize is that airborne contaminant issues create a cascade of effects throughout the project lifecycle," explains Dr. Lidia Morawska, director of Queensland University of Technology's International Laboratory for Air Quality and co-organizer of Stanford's 2025 Forum on Sustainable and Healthy Buildings. "The key is understanding which projects and activities warrant comprehensive controls versus targeted approaches."

1. Strategic Dust Control: Preventing Costly Finish Work Rework

Perhaps the most direct way better air quality management reduces costs is by preventing the need to redo finish work due to dust contamination. This is particularly critical during drywall sanding, concrete cutting, and other high-dust-generating activities that occur near the end of projects when schedules are tight and budgets are strained.

The Problem:

Airborne dust from construction activities settles on surfaces throughout the building, potentially contaminating:

-

Freshly painted surfaces

-

HVAC systems and ductwork

-

Sensitive electronic equipment

-

Finish flooring and cabinetry

-

Ceiling systems and light fixtures

A 2024 industry analysis by the Construction Industry Institute found that dust-related rework can account for 3-7% of total project costs on commercial construction projects, with even higher percentages on healthcare and technology facilities. This study was based on surveys of 32 owner representatives across the U.S. Gulf Coast region, primarily focused on commercial office and healthcare projects over $5 million.

The Solution:

Implementing a three-tiered approach to dust control based on NIOSH recommendations:

-

Source Capture: Using direct source-capture air cleaners at the point of generation provides the most effective way to remove welding fumes, soldering smoke and dust before they enter the workspace air

-

Area Containment: Employing temporary barriers and negative air pressure in work zones (secondary control)

-

Air Filtration: Deploying negative-pressure HEPA air scrubbers throughout the project helps maintain compliance by trapping 99.96% of airborne particles and odors

-

This hierarchy of controls aligns with OSHA's recommended approach for hazard mitigation, with source capture being the most effective method

Real-World Impact: Project-Specific ROI

The return on investment for dust control varies significantly by project type. Based on industry data and case studies, here's how different project categories typically perform:

Tier 1: Healthcare, Data Centers, Cleanrooms

-

Dust Control Investment: 1.50–2.50/ft²

-

Typical Rework Avoidance: 5–8/ft²

-

Net ROI Range: 2×–3× (high certainty)

A 2025 case study published in the Journal of Construction Engineering and Management documented the following results from implementing comprehensive dust control on a 120,000-square-foot hospital renovation in Boston:

-

91% reduction in dust-related rework on finish surfaces

-

127,000 indirect cost savings from avoided rework (against a 45,000 investment in controls)

-

8-day reduction in overall schedule

-

Zero dust-related warranty claims after 6 months of occupancy

The study authors (Wang, Huang, & Patel) used a before/after comparison methodology with detailed tracking of rework hours and material costs.

Tier 2: Mid-Range Office/Commercial Interiors

-

Dust Control Investment:0.75–1.25/ft²

-

Typical Rework Avoidance: 1–2/ft²

-

Net ROI Range: 1.2×–1.6× (moderate certainty)

Tier 3: Value-Grade Retail, Warehouses, Small Build-Outs

-

Dust Control Investment: 0.20 – 0.50/ft²

-

Typical Rework Avoidance: 0–0.25/ft²

-

Net ROI Range: 0.5×–1.2× (low to mixed; sometimes negative)

-

A retail tenant fit-out case study from Des Moines (2024) showed that for an 8,000 ft² basic sheetrock/paint project with no drywall texturing:

-

Investment: 8,000 on barriers and a single rental HEPA (125/day × 60 days)

-

Outcome: Only $1,200 in finish rework saved (a few paint touch-ups)

-

Net: -$6,800 (ROI = 0.15×)

This demonstrates that on small, straightforward interiors with limited dust-sensitivity, full-scale controls can be financially counterproductive.⁷

"The ROI for dust control isn't universal," notes a senior project manager at a major East Coast construction firm. "On high-end healthcare projects, every dollar invested in proactive dust control might return $4-6 in avoided rework costs. But on basic tenant improvements, the same investment might barely break even. The key is matching your approach to your specific project type."

2. OSHA Compliance: Avoiding Costly Citations and Work Stoppages

While OSHA does not have a specific standard for "indoor air quality" in construction, it does regulate numerous specific airborne contaminants through various standards. Particularly relevant to construction are standards for:

-

Respirable crystalline silica (29 CFR 1926.1153)

-

Welding fumes (29 CFR 1926.353)

-

Lead (29 CFR 1926.62)

-

Asbestos (29 CFR 1926.1101)

-

General requirements for ventilation (29 CFR 1926.57)

The financial implications of non-compliance with these specific standards have increased substantially in recent years.

The Stakes:

As of January 2025, OSHA penalties have been adjusted upward:

-

Serious violations: Maximum penalty increased from 16,131 to 16,550 per violation

-

Willful or repeated violations: Maximum penalty increased from Maximum penalty increased from 161,323 to 165,514 per violation.

-

Beyond these direct costs, OSHA citations often trigger work stoppages, compliance documentation requirements, and increased scrutiny on future inspections—all of which impact project timelines and costs.

The Solution:

A proactive compliance program that addresses specific regulated contaminants:

-

Exposure Monitoring: Regular testing of air quality for specific contaminants like silica, lead, and welding fumes

-

Written Exposure Control Plans: Documented procedures for different construction activities as required by specific OSHA standards

-

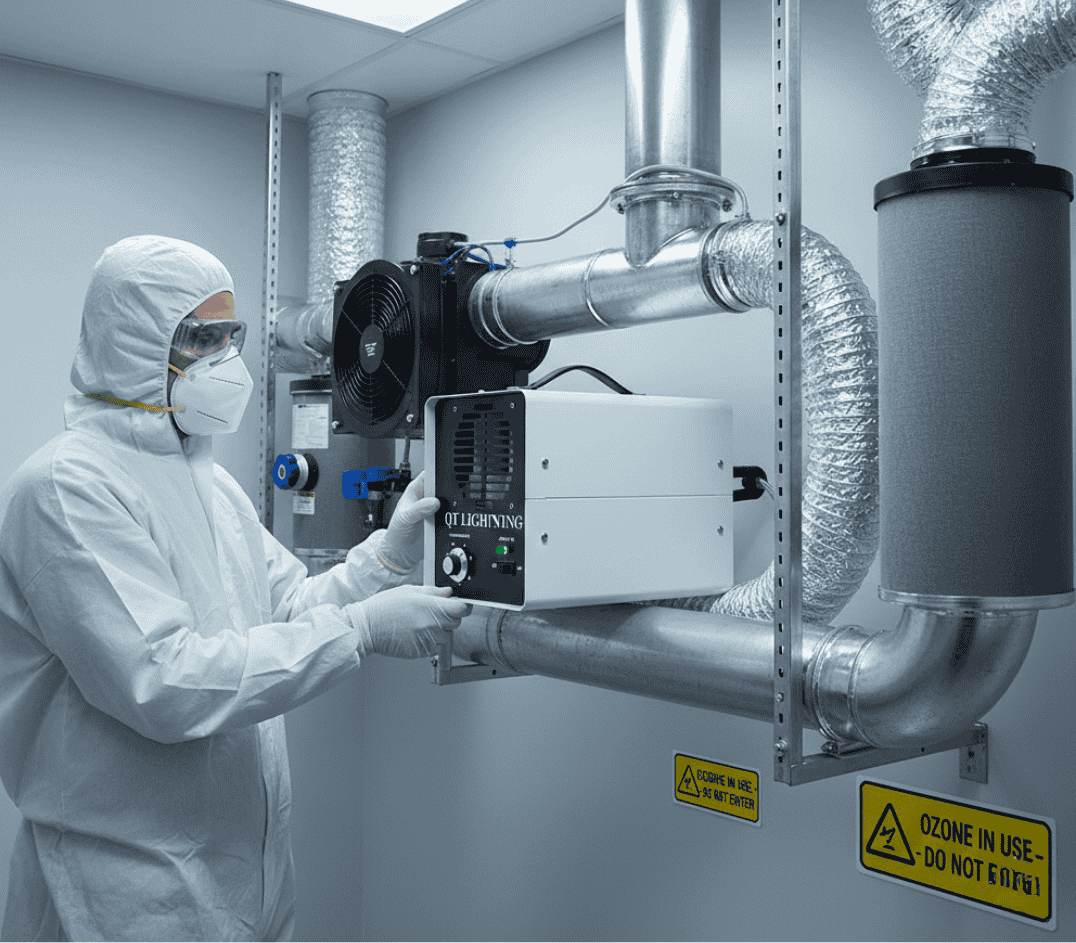

Engineering Controls: Appropriate ventilation and filtration systems designed for specific contaminants. For a deeper look at how portable HEPA scrubbers support OSHA’s silica-dust rules, see our job-site HEPA scrubber guide.

-

Training: Worker education on specific hazards and controls

-

Documentation: Maintaining records of all monitoring and control activities

Real-World Impact: When Compliance Programs Matter Most

It's important to note that OSHA citation risk varies dramatically by project type and activities performed. Projects involving significant concrete cutting, masonry work, abrasive blasting, or extensive welding face much higher regulatory scrutiny than those without these activities. When projects involve heavy welding or high dust loads, check our CFM sizing formulas for welding bays to calculate ventilation needs and compare system performance.

A multi-site analysis of commercial construction projects published by the Associated General Contractors in 2024 (n=78 general contractors across 10 states) found that contractors with comprehensive contaminant control programs experienced:

-

76% fewer OSHA citations related to specific air contaminants

-

94% reduction in work stoppage days

-

Average savings of $83,000 per project in avoided penalties and compliance costs

-

Significantly faster inspections with fewer follow-up requirements

However, this study primarily examined contractors performing regulated activities like concrete cutting and demolition. For projects without these specific activities—such as many retail fit-outs or office renovations using pre-cut components—the citation risk (and associated financial benefit of compliance programs) is substantially lower.

"Even with comprehensive monitoring and written plans, you're not guaranteed zero citations," explains an OSHA compliance specialist who works with construction firms on the West Coast. "For example, if your project involves renovation of an older building, an inspector could still cite you for a dropped pellet of lead paint from vintage structural beams, despite your air sampling program for silica."

3. Enhanced Productivity: The Performance Impact of Clean Air

While rework and regulatory compliance represent obvious cost centers, the productivity impact of air quality may deliver significant financial returns in certain contexts. The EPA has documented the relationship between air quality and worker performance across multiple industries, though construction-specific data shows more variable results.

The Evidence:

A 2024 study published in the Journal of Construction Engineering and Management examined worker productivity across 24 commercial construction sites with varying levels of airborne contaminants. The methodology involved comparing similar crews performing identical tasks in different air quality environments, controlling for other variables like crew experience and weather conditions. The findings showed:

-

Workers in environments with lower particulate levels (PM2.5 <12 μg/m³) completed tasks 9-14% faster than those in environments with higher particulate levels

-

Error rates decreased by 27% in cleaner air environments

-

Absenteeism was 22% lower on projects with comprehensive dust and fume control

-

Workers reported significantly higher job satisfaction and engagement¹⁰

-

These productivity gains translate directly to labor costs, which typically represent 30-40% of total construction budgets.

Important Context:

It's crucial to note that while these findings are compelling, they represent controlled comparisons where other variables were held constant. On real job sites, factors like weather delays, material shortages, or design changes can sometimes outweigh productivity gains from cleaner air. Additionally, if crews are forced to wait for "optimal" air quality conditions, the schedule impact could potentially offset productivity benefits.

The Solution:

Implementing a worker-centered approach that includes:

-

Real-time Monitoring: Deploying sensors for specific contaminants throughout the project to identify problem areas

-

Targeted Ventilation: Providing additional fresh air in densely occupied work zones

-

Clean Air Stations: Creating designated areas with enhanced filtration for breaks and detailed work

-

Education: Helping workers understand the connection between air contaminants and performance

-

Feedback Mechanisms: Enabling workers to report concerns before they impact productivity

Real-World Impact: When Productivity Benefits Are Greatest

Productivity benefits from air quality management are most pronounced in:

-

Labor-Intensive Projects: Where labor represents >35% of total costs

-

Precision Work: Tasks requiring fine motor skills and attention to detail

-

Extended Duration Activities: Work lasting several weeks or months in the same area

- Projects with Skilled Labor Shortages: Where maximizing existing workforce productivity is critical

A 2025 case study published in the American Journal of Industrial Medicine documented the following results from implementing these strategies on a hospital renovation project in California:

-

11% increase in overall labor productivity (measured as completed work units per labor hour)

-

3.2% reduction in overall project schedule

-

Significant improvement in subcontractor coordination and satisfaction

"We initially implemented enhanced controls for compliance reasons," notes the project executive. "What surprised us was the impact on productivity. Workers performed better, made fewer mistakes, and collaborated more effectively in a cleaner air environment. However, we've seen less dramatic results on simpler projects with less precision work."

4. Quality Assurance: Reducing Defects and Warranty Claims

The Problem:

Airborne contaminants can compromise:

-

Paint and coating application and curing

-

Adhesive performance in flooring and wall coverings

-

Concrete finishing and curing

-

Electronics and control system installation

-

HVAC system cleanliness and performance

These issues often manifest as defects during final inspection or, worse, as warranty claims after occupancy. According to data from the Construction Industry Institute, dust-related defects account for approximately 14% of punch list items and 11% of post-occupancy warranty claims.

The Solution:

Implementing process-specific controls:

-

Material-Specific Protocols: Tailoring dust and contaminant control requirements to specific installation processes

-

Environmental Monitoring: Tracking temperature, humidity, and particulate levels during critical installations

-

Temporary Filtration: Providing enhanced filtration during sensitive operations

-

Sequencing Optimization: Scheduling high-dust activities to minimize impact on sensitive installations

-

Pre-Occupancy Flush-Out: Thoroughly cleaning the air before turnover, as recommended by ASHRAE and the USGBC

Alternative Approaches: Beyond Equipment-Based Solutions

Many successful contractors implement lower-cost administrative and scheduling controls that can be equally effective:

Administrative Controls:

-

Require mandatory use of on-tool vacuums on every grinder and saw

-

Implement a "Tool-Attachment Incentive" program ($50 bonus per crew member with zero "tool with no vacuum" infractions per week)

-

Some general contractors find a simple 98% compliance rate with tool-vacuum requirements reduces dust rework by 40–50%—achieved for 2,000 incentives versus 15,000 in HEPA rentals

Scheduling & Sequencing Controls:

-

Schedule dust-generating activities like drywall sanding only on weekends or nights when no sensitive trades are present

-

By shifting 80 hours of sanding to off-peak times, crews can avoid contaminating final finishes altogether

-

On a 200,000 fit−out, this approach can eliminate 10,000–$15,000 in rework with minimal additional cost

Prefabrication/Pulled-to-Order Approaches:

-

Use pre-cut, pre-finished millwork delivered ready for install—no on-site routing or finishing

-

Interiors can maintain much lower particulate levels during install

-

This approach can reduce rework by 60% at a marginal cost of 5% above off-the-shelf carpentry

Real-World Impact: Quality Outcomes by Project Type

A comparative analysis published in the Journal of Building Engineering in 2024 examined 15 similar commercial projects and found that those with comprehensive contaminant control programs experienced:

-

68% fewer dust-related punch list items (n = 123 vs. n = 385 on control projects)

-

82% reduction in post-occupancy warranty claims related to dust contamination (from 17 to 3 in sample)

-

9.4% higher client satisfaction scores

-

Significantly faster project closeout and final payment¹³

However, the study authors noted that quality benefits were most pronounced in projects with extensive finish work, sensitive equipment installation, or complex HVAC systems. Basic tenant improvements showed less dramatic quality improvements from enhanced air quality management.

5. Client Satisfaction and Reputation: The Business Case for Air Quality Excellence

Perhaps the most compelling reason to prioritize air quality management is its potential impact on client relationships and company reputation. As building owners become increasingly aware of the importance of clean air, contractors who excel in this area may gain a competitive advantage—though client priorities still vary significantly.

The Trend:

Recent market research by Dodge Data & Analytics indicates growing client expectations around air quality:

-

76% of commercial building owners now include specific dust control requirements in construction contracts

-

82% of healthcare and education clients specifically evaluate contractors' air quality management capabilities

-

64% of owners report that air quality performance influences future contractor selection

-

91% of occupants express concern about building air quality post-COVID¹⁴

These trends are particularly pronounced on the East and West coasts, where environmental awareness and regulatory pressures are highest.

Important Distinction:

It's crucial to distinguish between construction-phase air quality management and operational indoor air quality (IAQ) in completed buildings. While the 91% occupant concern statistic reflects interest in operational IAQ (HVAC filter ratings, airflow volumes, CO₂ levels), this doesn't always translate directly to construction-phase requirements. Many owners separate "construction-phase controls" from "long-term IAQ warranties."

The Solution:

Positioning your company as a leader in air quality management through:

-

Documented Expertise: Developing and promoting your firm's capabilities in controlling specific construction contaminants

-

Transparent Monitoring: Providing clients with real-time data throughout the project

-

Certification: Pursuing relevant certifications for your company and key personnel

-

Case Studies: Documenting and sharing success stories from previous projects

-

Post-Occupancy Support: Offering guidance during the transition to occupancy

Client Satisfaction Context:

It's important to recognize that client satisfaction often correlates most strongly with on-time delivery and staying on budget. If a contractor nails a tight schedule but has minimal dust controls, the client may overlook some dust issues if the opening date isn't delayed. Conversely, a contractor who obsessively polishes every corner but is two weeks late may earn a poor client rating despite spotless air quality.

Real-World Impact:

Contractors who have established reputations for excellence in air quality management report business benefits according to a 2025 industry survey (n=45 general contractors specializing in commercial construction):

-

Higher success rates in competitive bidding (12-18% improvement)

-

Ability to command premium pricing (3-7% higher margins)

-

Stronger client retention and repeat business (22% higher than industry average)

-

Reduced insurance premiums due to lower risk profiles

-

Enhanced ability to attract and retain skilled workers

"We've transformed air quality management from a compliance issue to a core value proposition," shares the CEO of a mid-sized general contracting firm specializing in healthcare and technology projects. "Our clients know that when they hire us, they're getting a contractor who will protect both their workers and their investment through superior contaminant control. But we're also realistic—we tailor our approach to each project type rather than applying the same expensive controls everywhere."

Worker Health and Long-Term Liability: The Often Overlooked Factor

Beyond immediate project benefits, air quality management has significant implications for worker health and long-term liability that extend far beyond any single project budget.

Chronic Disease & Future Costs:

-

Long-term silica or asbestos exposure can lead to 200,000–200,000–200,000–400,000 lifetime medical costs per worker¹⁶

-

A single worker's silicosis claim (with legal fees, indemnity, lost productivity) can cost a contractor $500,000+—not covered in a single project budget

-

Losing two key journeymen (at 40/hr senior wage) for silicosis litigation can cost 50,000 in replacement training—far exceeding one project's dust program investment

Insurance Premium Reductions:

-

Contractors who document robust air-quality programs often negotiate 5–10% lower Workers' Comp rates

-

Some carriers provide immediate credits for NIOSH-certified equipment use

Reputation & Recruitment:

-

Younger tradespeople increasingly choose employers with documented safety metrics

-

A reputation for "zero dust" can be a recruiting advantage in unions

Implementation: Practical Steps for Better Air Quality on Your Next Project

Translating these insights into action requires a systematic approach tailored to your specific project types and challenges. Here's a practical implementation framework based on NIOSH and OSHA guidelines:

1. Project-Specific Assessment

- Conduct a contaminant risk assessment during pre-construction

- Identify high-risk activities and sensitive installations

- Develop a project-specific exposure control plan for regulated substances

- Establish clear performance metrics and monitoring protocols

- Critical Step: Perform a cost-benefit analysis specific to your project type and scope:

- Estimate likely dust control costs (rentals, barriers, labor, training)

- Estimate potential rework costs (multiply expected dust level by square footage of sensitive finishes × cost per sq ft)

- Compare before finalizing your approach and budget

2. Tiered Control Strategy

Tier 1: Healthcare, Data Centers, Cleanrooms

-

Comprehensive negative pressure containment

-

HEPA filtration throughout

-

Real-time particulate monitoring

-

Dedicated dust control supervisor

Tier 2: Mid-Range Office/Commercial Interiors

-

Targeted containment in high-dust areas

-

Strategic HEPA placement

-

Regular (but not continuous) monitoring

-

Dust control responsibilities assigned to existing supervision

Tier 3: Value-Grade Retail, Warehouses, Small Build-Outs

-

Focus on source capture (tool vacuums)

-

Simple plastic barriers for major dust activities

-

Visual monitoring

-

Basic training for all workers

Sizing & Selection Tools

Properly sizing your equipment is essential for effective dust and fume control. Use our Smoke-Eater CFM Calculator to determine the right airflow requirements for your space, or request a custom plan through our Smoke-Eater Recommendation Form for expert, no-obligation guidance.

3. Alternative Control Methods

-

Consider these approaches before investing in expensive equipment:

-

Administrative Controls: Tool vacuum requirements, clean-as-you-go policies

-

Scheduling Controls: Isolating dust-generating activities temporally

-

Prefabrication: Moving dust-generating work off-site

-

Behavioral Incentives: Rewarding dust-free practices

-

Maintain comprehensive records of all management activities

-

Quantify the benefits of your program in terms of cost savings and quality improvements

-

Share success stories with clients and prospects

-

Continuously refine your approach based on project outcomes

American-Made Solutions for Construction Air Quality

When selecting equipment and systems for your air quality management program, American manufacturers offer several distinct advantages:

-

Regulatory Alignment: Equipment designed specifically for U.S. construction environments and OSHA compliance requirements

-

Durability: Robust construction designed to withstand the harsh conditions of active job sites

-

Technical Support: Local expertise and rapid response for troubleshooting and optimization

-

Customization: Ability to tailor solutions to specific project requirements and challenges

-

Integration: Seamless compatibility with other construction systems and processes

Leading American manufacturers offer comprehensive solutions specifically designed for construction applications, including portable HEPA air scrubbers, negative air machines, dust containment systems, and real-time monitoring equipment.

Conclusion: A Balanced Approach to Air Quality Management

As we've seen, better management of construction airborne contaminants can deliver measurable returns across multiple dimensions of project performance—but these benefits vary significantly by project type, activities performed, and implementation approach.

The most successful contractors:

1. Match their approach to project type: Using comprehensive controls for sensitive environments and targeted approaches for basic build-outs

2. Focus on source capture first: Prioritizing tool vacuums and local extraction before expensive ambient filtration

3. Consider administrative alternatives: Implementing scheduling and behavioral controls that can be more cost-effective than equipment

4. Account for long-term health impacts: Recognizing that worker protection delivers benefits beyond any single project

5. Quantify and communicate results: Tracking the specific benefits of their air quality investments

By taking a balanced, evidence-based approach to air quality management, you can protect both your immediate project outcomes and your long-term business interests—while avoiding unnecessary costs on projects where simpler approaches may suffice.

For assistance with your specific air quality challenges or to explore American-manufactured air purification solutions trusted by leading contractors nationwide, reach out to Pure N Natural specialists who understand the unique demands of construction environments. Your workers, clients, and balance sheet will all breathe easier as a result.