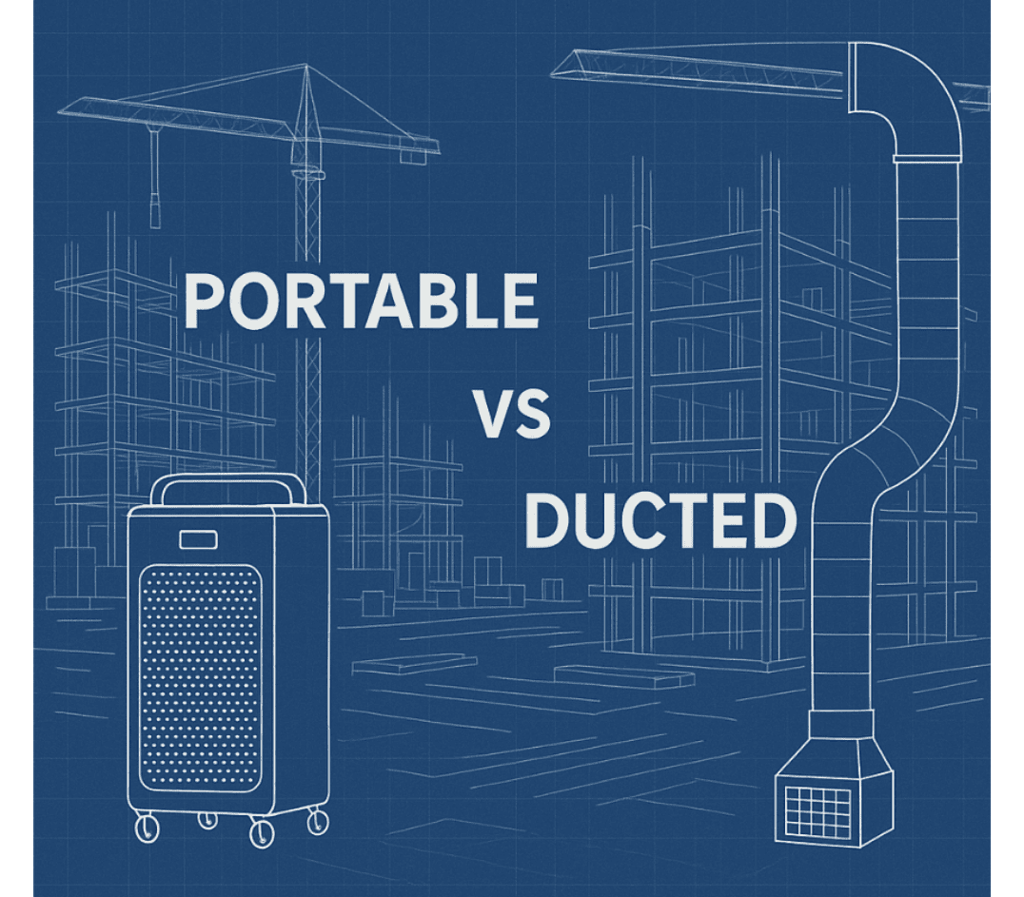

Rapid building puts you under pressure. Each decision affects your timetable, costs, and compliance. When it comes to airborne cleaners in an accelerated project, the choice between portable or ducted air cleaning systems must be assessed on a project-specific basis rather than a blanket solution.

This document compares portable and ducted air-cleaning devices for fast-tracked construction to help practitioners choose the best option. It does so using authoritative guidance from OSHA, ASHRAE, and SMACNA. We’ll look at documented costs, timelines, performance data, and recommendations for your project to help make an informed decision.

The Fast-Track Air Quality Challenge

Fast-track construction jobs have a distinctive air quality management issue that needs to be addressed while coordinating quick computation.

- Tight timeframes leave little room to install permanent HVAC systems.

- Multiple trades occurring simultaneously create varying contamination profiles.

- Phased occupancy may require different solutions in separate zones.

- Compliance must be maintained even on an accelerated schedule.

- Budget constraints demand judicious spending of every dollar.

Although OSHA does not mandate the use of any specific air cleaning system, its Technical Manual (Section III, Chapter 3) states: “Engineering controls are the preferred method for reducing the exposure of the employee to air contaminants.”

Both portable and ducted systems can be considered engineering controls if done properly.

Portable Air Cleaners: Quick to Deploy

Portable air cleaning units have evolved from simple filtration boxes to advanced air quality management systems built for construction, featuring built-in monitors and multi-stage filtration.

Advantages for Fast-Track Projects

- Rapid deployment: Operational within minutes, with relatively quiet operation.

- Flexibility: Easily reposition units as work progresses.

- No design integration: Avoids delays associated with building design.

- Scalability: Add or remove units to match project phases.

- Lower upfront cost: Self-contained HEPA units cost $1,500–$5,000 each (2025).

Limitations to Consider

- Coverage area: Effective only over ~500–1,500 sq ft per unit, depending on ceiling height and airflow.

- Recirculation: Most units recirculate filtered air (not exhausting outside), which may be inadequate for carcinogen-producing operations.

- Floor space: Units occupy 6–10 sq ft of floor, potentially impeding high-traffic areas.

- Power requirements: Must coordinate with temporary electrical distribution to avoid overloads.

- Filter standards: Ensure true HEPA (99.97% @ 0.3 microns); ASHRAE 52.2 recommends minimum MERV 13 for construction dust, HEPA (MERV 17+) for fine particulates.

Ducted Air Cleaning Systems: The Combined Approach

Ducted units integrate with temporary or permanent HVAC systems to provide whole-building or zone-specific filtration. Configurations range from inline filter boxes to complete air-handling units.

Advantages for Fast-Track Projects

- Uniform air quality: Consistent filtration across entire zones.

- Negative pressure: Containment of dust migration—recommended by SMACNA for occupied renovations.

- Exhaust capability: Preferred for hazardous contaminants (NIOSH/OSHA).

- Space efficiency: Installed overhead or in mechanical rooms, freeing floor space.

- Permanent integration: Can transition into the building’s HVAC, reducing long-term costs.

Limitations to Consider

- Longer lead time: Design, installation, and commissioning typically take 5–10 working days (ASHRAE).

- Higher cost: Temporary ducted systems run $15,000–$50,000 (equipment) plus $10,000–$20,000 installation and $5,000–$10,000 engineering (2025).

- Inflexibility: Difficult and costly to modify once installed.

- Coordination: Requires close scheduling with other trades and HVAC specialists.

- Additional subcontractor: More vendors to manage on compressed timelines.

The Costs and Benefits of the Decision

Beyond equipment price, consider installation, operations, and schedule impacts. Data derived from RSMeans 2025 and industry case studies.

Initial Investment Comparison (2025 Figures)

|

System Type |

Equipment Cost |

Installation Cost |

Design/Engineering |

Total Initial Investment |

|---|---|---|---|---|

|

Portable (10,000 sq ft coverage) |

$15,000-$25,000 |

$0-$1,000 |

$0-$500 |

$15,000-$26,500 |

|

Ducted (10,000 sq ft coverage) |

$25,000-$40,000 |

$10,000-$20,000 |

$5,000-$10,000 |

$40,000-$70,000 |

Operational Cost Comparison (Monthly)

|

System Type |

Energy Costs |

Filter Replacement |

Maintenance Labor |

Total Monthly Cost |

|---|---|---|---|---|

|

Portable |

$500-$800 |

$400-$700 |

$300-$600 |

$1,200-$2,100 |

|

Ducted |

$600-$1,000 |

$300-$500 |

$200-$400 |

$1,100-$1,900 |

Project Timeline Impact

According to a 2024 study by the Construction Industry Institute, the implementation timeline differences between systems can significantly impact fast-track projects:

|

System Type |

Design Time |

Procurement |

Installation |

Commissioning |

Total Lead Time |

|---|---|---|---|---|---|

|

Portable |

0-1 days |

1-5 days |

0-1 days |

0-1 days |

1-7 days |

|

Ducted |

3-7 days |

5-10 days |

3-7 days |

1-2 days |

12-26 days |

On projects with liquidated damages of $5,000-$15,000 per day (common on fast-track commercial projects), portable systems' schedule advantage can represent significant cost avoidance.

ROI Factors Beyond Direct Costs

- Schedule savings: Portable units can save 1–3 weeks of critical path time.

- Space utilization: 6–10 sq ft per unit—may affect productivity in tight areas.

- Labor efficiency: Poor air quality can reduce productivity by 3–7% (EPA).

- Compliance: Both systems ensure OSHA compliance when sized correctly; portability allows rapid response to inspections.

Real-World Performance: What the Data Shows

A 2024 study in the Journal of Occupational and Environmental Hygiene compared 24 fast-track projects using portable vs. ducted systems.

Particulate Matter Reduction

- Portable: 78–85% reduction (properly sized/placed)

- Ducted: 82–91% reduction (well-balanced)

Consistency of Air Quality

- Portable: ±18% variation

- Ducted: ±7% variation

Adaptability to Changing Conditions

- Portable: 8.4/10

- Ducted: 5.2/10

Overall Compliance Success

- Portable: 92% continuous compliance

- Ducted: 94% continuous compliance

Decision Framework: Matching Solutions to Project Types

Based on performance, cost, and guidelines from ASHRAE, SMACNA, and OSHA:

Portable Systems Are Typically Better For

- Renovation in non-sensitive areas (no ducting, sequential activities)

- Phased occupancy (different zones at different times)

- Short projects (< 6 months)

- Uncertain scopes (flexibility needed)

- Limited budgets (lower capital outlay)

Ducted Systems Are Typically Better For

- Healthcare/sensitive renovations (negative pressure + HEPA)

- Long projects (> 9 months) (offset by lower operating costs)

- Large open areas (consistent coverage)

- Occupied renovations (containment of contaminants)

- Hazardous material abatement (exhaust to outdoors)

Combining Strengths: The Hybrid Approach

A hybrid system leverages both technologies. SMACNA endorses this for many fast-track projects, and an AGC 2025 study found that 68% of successful projects used hybrids.

Typical Hybrid Implementation

- Ducted systems for main construction zones or HVAC-connected areas.

- Temporary portable units for high-dust activities (concrete cutting, drywall sanding).

- Mobile units for rapid redeployment based on inspections or changing needs.

Best Practices for Implementation

For Portable Systems

- Strategic placement: Arrange units in circles to create “clean→dirty” airflow (ASHRAE).

- Right-sizing: Calculate CFM from room volume and desired air changes (4–6 ACH general; 10–15 ACH heavy dust).

- True HEPA verification: Ensure filters meet 99.97% @ 0.3 µm standards.

- Monitoring integration: Use real-time alarms for performance drops or filter changes.

- Maintenance documentation: Log filter changes and performance tests for regulators.

For Ducted Systems

- Modular design: Create reconfigurable components for evolving needs.

- Air balance testing: Test at installation and monthly thereafter (SMACNA).

- Filter staging: Use pre-filters to extend final filter life.

- Negative pressure verification: Monitor with manometers or gauges.

- Commissioning protocol: Verify performance upon installation and after major changes.

Case Studies

East Coast Mixed-Use Development

- Location: 12-story Boston project (14 months)

- Approach: Hybrid (ducted negative air on floors 1–4; portable HEPA on floors 5–12)

- Results:

- 22% cost reduction vs. all-ducted

- 15% improved consistency vs. all-portable

Zero citations/violations - Rapid adaptation when the top-floor schedule accelerated

West Coast Technology Campus

- Location: California tech campus (10 months)

- Approach: Temporary ducted systems tying into permanent HVAC; high-capacity portable for labs; real-time monitoring

- Results:

- Continuous compliance with strict regulations

- Seamless switch to permanent filters

- 8% schedule acceleration from cleaner air

$450,000 savings via avoided delays/rework

Key Questions to Ask

- Project duration and amortization impact?

- Frequency of area shifts during construction?

- Contaminants of concern for your activities?

- Critical path impacts from cleaner installation?

- Regulatory requirements to meet?

- Phased occupancy considerations?

- Power and space availability for equipment?

- Integration with other building systems?

The American Manufacturing Advantage

- Regulatory expertise: Equipment designed to meet OSHA, ASHRAE, and local codes.

- Rapid availability: Shorter lead times than overseas sourcing.

- Local support: On-site assistance for design and troubleshooting.

- Customization: Quick modifications to standard equipment.

- Parts availability: Readily available filters and components.

- Comprehensive solutions: Portable HEPA scrubbers & ducted negative air systems tailored for fast-track environments.

Conclusion: A Balanced Approach to Fast-Track Air Quality

The choice between portable and ducted systems hinges on matching the right solution—or combination—to your project’s requirements, timeline, and budget. By applying the evidence-based comparisons and guidelines herein, you can optimize air quality, productivity, and compliance. Remember, the lowest initial cost isn’t always the most economical over the project lifecycle.

For expert assistance or to explore American-manufactured air purification solutions trusted by professionals nationwide, reach out to specialists experienced in fast-track construction environments.

References

- ASHRAE (2023). Creating Cleaner Air: Design Guide for Building Construction and Renovation.

- SMACNA (2022). IAQ Guidelines for Occupied Buildings Under Construction (3rd Ed.).

- OSHA (2022). Technical Manual, Section III, Chapter 3: Ventilation Investigation.

- NIOSH (2022). Engineering Control of Welding Fumes, Pub. No. 75-137.

- EPA (2023). Indoor Air Quality and Productivity.

- Journal of Occupational and Environmental Hygiene (2024). Comparative Analysis of Air Cleaning Technologies in Fast-Track Construction Projects.

- Construction Industry Institute (2024). Implementation Timeline Analysis for Construction Air Quality Management Systems.

- RSMeans (2025). Construction Cost Data. Gordian Group.

- Associated General Contractors of America (2025). Case Studies in Construction Air Quality